Led Lighting Factory

Ever question exactly how an LED light bulb is created? Perhaps not the tiny colored lights, nevertheless huge, bright, solid-state bulbs gradually changing incandescent and small fluorescent lighting effects every where? By way of an offshoot associated with the Taiwanese company Glacialtech, which makes PC energy products and heatsinks, PCSTATS features built a virtual factory trip of their GlacialLight LED lighting effects plant located in DongGuan, China.

Ever question exactly how an LED light bulb is created? Perhaps not the tiny colored lights, nevertheless huge, bright, solid-state bulbs gradually changing incandescent and small fluorescent lighting effects every where? By way of an offshoot associated with the Taiwanese company Glacialtech, which makes PC energy products and heatsinks, PCSTATS features built a virtual factory trip of their GlacialLight LED lighting effects plant located in DongGuan, China.

Light-emitting Diode technology has existed since the late 1960's, and also for the very first 40 many years LEDs had been mainly found in electronic devices devices to restore mini bulbs. In the last decade or so, advances when you look at the technology eventually boosted light result sufficient for LEDs to start to seriously compete with the bulb - technology which is a +100 years of age.

Brief History of Light Emitting Diodes

Your message LED is actually an acronym for led, a great condition electric circuit that, in simplified terms, creates light by the action of electrons in a semiconductor material.

Light-emitting Diode lights have become energy-efficient, but several challenges must be overcome before we are happy to spend inexpensive incandescent and reasonably energy-efficient small fluorescent light bulbs. The very first is top-notch light. Compared to a consistent incandescent bulb, white light created by LEDs might have an unpleasant bluish or purple tint.

Just like most technologies, each successive LED generation improves light high quality, the actual quantity of light production per Watt, and decreases price as well as heat. Age solid state general purpose lighting is approaching fast.

Crosswalk Signs to Architectural Lighting

Crosswalk Signs to Architectural Lighting

Glacialtech make computer system CPU heatsinks and PC power products, so it is unsurprising your organization recently expanded to the developing marketplace for solid state LED lighting products.

In North America LED architectural illumination is simply starting to take hold, but if you've visited Hong-Kong, Shanghai or just about any other significant town in China you will have experienced multi-coloured Light-emitting Diode illumination decorating every skyscraper coming... And those friendly green electronic count-down crosswalk signs, store illumination, and countless purple automobile end lights.

Building-sized LED lighting effects for complete movement advertising in Shanghai, China.

Components of a Light-emitting Diode Light

a LED light is made from four important elements; the Light-emitting Diode circuit board, a heatsink and power-supply, and layer.

The lights start off as bare printed circuit panels (PCB) and high luminance LED elements arrive from individual factories which concentrate on making those components. LED elements themselves develop some temperature, so that the PCB utilized in lighting fixtures is only a little unique. Instead of the standard non-conductive sandwich of epoxy and fiberglass, the circuit board is laid out on a thin sheet of aluminum which will act as a heatsink.

The aluminum PCB found in Light-emitting Diode illumination is coated with a non-conducting material and conductive copper trace outlines to make the circuit board. Solder paste is then used inside right places and then SMT devices (exterior Mount Technology) put the small Light-emitting Diode elements, motorist ICs and other components onto the board at ultra large speeds.

The aluminum PCB found in Light-emitting Diode illumination is coated with a non-conducting material and conductive copper trace outlines to make the circuit board. Solder paste is then used inside right places and then SMT devices (exterior Mount Technology) put the small Light-emitting Diode elements, motorist ICs and other components onto the board at ultra large speeds.

The round model of a conventional bulb means many LED printed circuit boards are circular, therefore for ease of handling several of the smaller circular PCBs are combined into one bigger rectangular PCB that automated SMT machinery are capable of. Think of it like a cupcake tray going from one machine to a higher along a conveyor buckle, then by the end the patient cupcakes tend to be snapped clear of the tray.

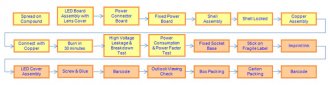

The manufacturing measures.

After the larger sheets of Light-emitting Diode circuit boards have actually passed away through a solder reflow range (a heat furnace that melts the solder paste), they've been separated in to the specific little circuit panels and power wires manually soldered on.

The little power supply housed in the body for the lamp undergoes an equivalent process, or might delivered total from another factory. Either way, the production tips are identical; initially the PCB passes through SMT outlines, then it goes to a manual DIP assembly line in which a lengthy row of factory employees add one element at any given time.

LED Bulb Factory Tour

Follow along as GlacialLight factory works assemble a BR30 LED spotlight. The light draws about 10W and outputs between 360lm to 540lm based if 6W or 9W Light-emitting Diode elements are utilized. Colour temperature is rated at 3000K or 6000K, according to the design. Life span is 35, 000 hours.

Exterior Mount Device (SMD) Line.

Carry on with, the tour goes on next web page even as we look at Light-emitting Diode modules being assembled into a PAR30 LED light bulb...

|

© 2016 PCSTATS.com

Please respect the full time and effort that moved into producing each PCSTATS Beginners Guide, usually do not illegally copy. Thank-you. |

|

||||

RELATED VIDEO

Share this Post

Related posts

LED Factory Lighting

Demonstrating its “aggressive approach to lead in environmental improvements, ” Ford Motor Co. said it is installing LED…

Read MoreLED Lighting Desk Lamp

Energy Conserving Vessels to Canada The clean and simple Equo Gen 3 Desk Lamp features a discreet counterweight design for…

Read More